Al-C Zr-C Submerged Nozzles

Product Description: Submerged nozzle prevent the splashing of steel stream and re-oxidation of molten steel,alters the flow status of steel stream and reduces the lash depth of steel stream to help impurity floating,heat distribution and homogeneous steel crystallization.

According to the requirements of our customers,we can provide non-preheat non-carbon nozzle,non-silicon nozzle,nozzle for Mn-steel and stainless steel and thin-wall steel productions,bended nozzle and square,circle and rectangle bricks,etc.

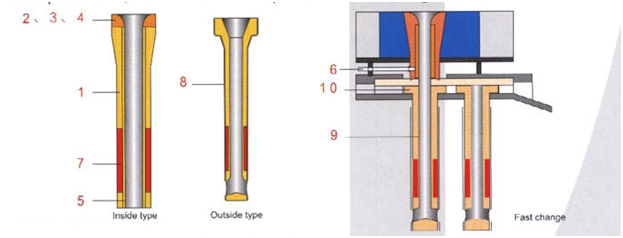

*Graphic illustration:

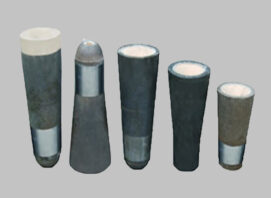

1.Standard Al-C body materials having corrosion and thermal shock resistances.

2.Standard Al-C materials for the bowl structure having high corrosion resistance.

3.Spinel materials for the bowl structure to assure better stopper and exceptional good resistance to slag corrosion.

4.Standard Mg-based materials for the bowl structure having good corrosion resistance to siag containing Ca.

5.Standard material to prevent Al2O3 adhesion inside the nozzle.

6.Standard argon injection structure to prevent air suction.

7.High quality Zr-based materials to assure good corrosion resistance to the slags with or without F.

8.Ceramic fiber blanket to prevent heat loss during casting.

9.Non-carbon liner to meet the requirements of low carbon steel,silicon steel and high purity steel productions.

10.composite surface materials to assure sealing and fast change.